Our Machining Process:

The Vanamatic Way

Built-In Automated Intelligence

Our state-of-the-art Vanamatic Business Manager allows us to respond quickly to our customers and prioritize production and inventory control for 100% on-time delivery and cost control.

Long-term customer relationships, along with innovative technology enhancements, provide competitive costs and price stability. Our proactive quality planning and immediate feedback on dimensional and daily analysis deliver in-control processes to ensure quality results.

(VBM)

Vanamatic Business Manager

Our proprietary VBM tool allows for the automation of all of the following processes, delivering higher efficiency and the assurance that we’re managing your inventory for you.

Shop floor management & prioritization

![]()

Forecasting and machine scheduling

![]()

Raw material planning

![]()

Inventory management

An Experienced Engineering Team

Our 3D modeling virtual environment enables us to design and visualize custom components with accuracy, while our in-house tooling design and manufacturing ensure unparalleled quality and efficiency.

We specialize in quick-change product families, providing fast, flexible product interchangeability that meets the evolving needs of our customers.

Vanamatic Quality Control Systems

Shop floor to quality lab integration

Full dimensional setup verification

Vision scanning throughout processes

Department-level quality ownership

Culture Built on

Efficiency & Innovation

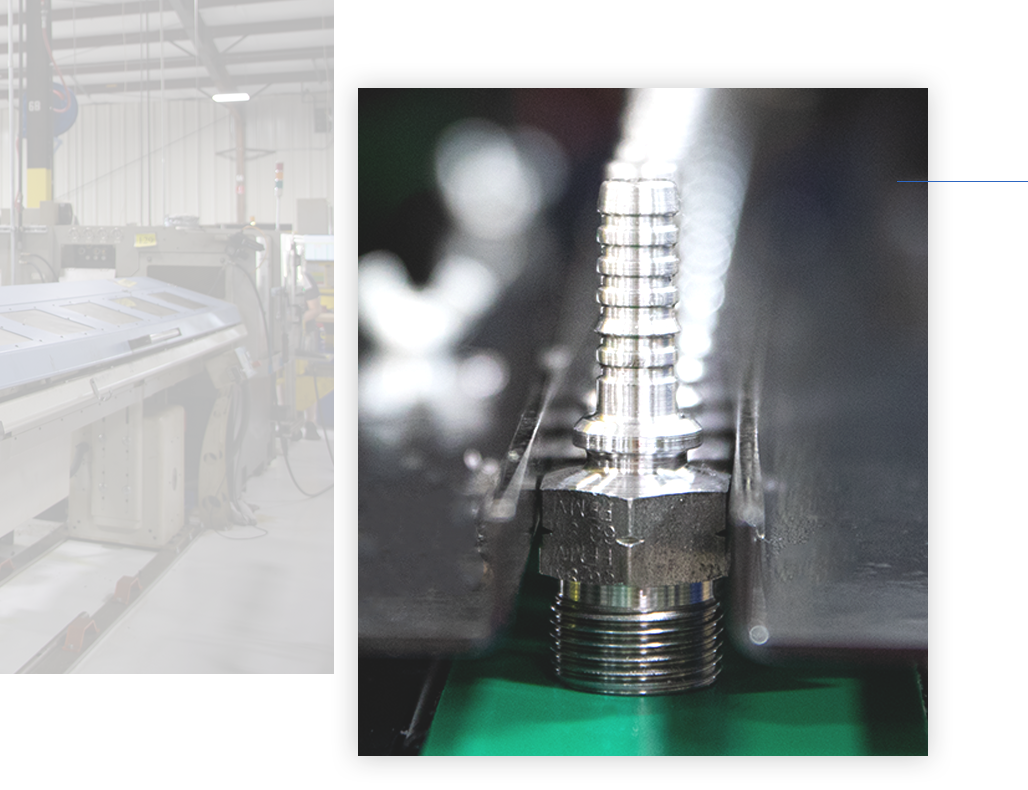

Vanamatic is dedicated to saving you time and money with our precision machining expertise. With a long history and mastery of screw machine rebuilds, we operate the best heavy screw machines on the planet. Our advanced manufacturing incorporates conveyors, cobots, sensors, cameras, and custom fabrications to deliver unparalleled efficiency and quality.