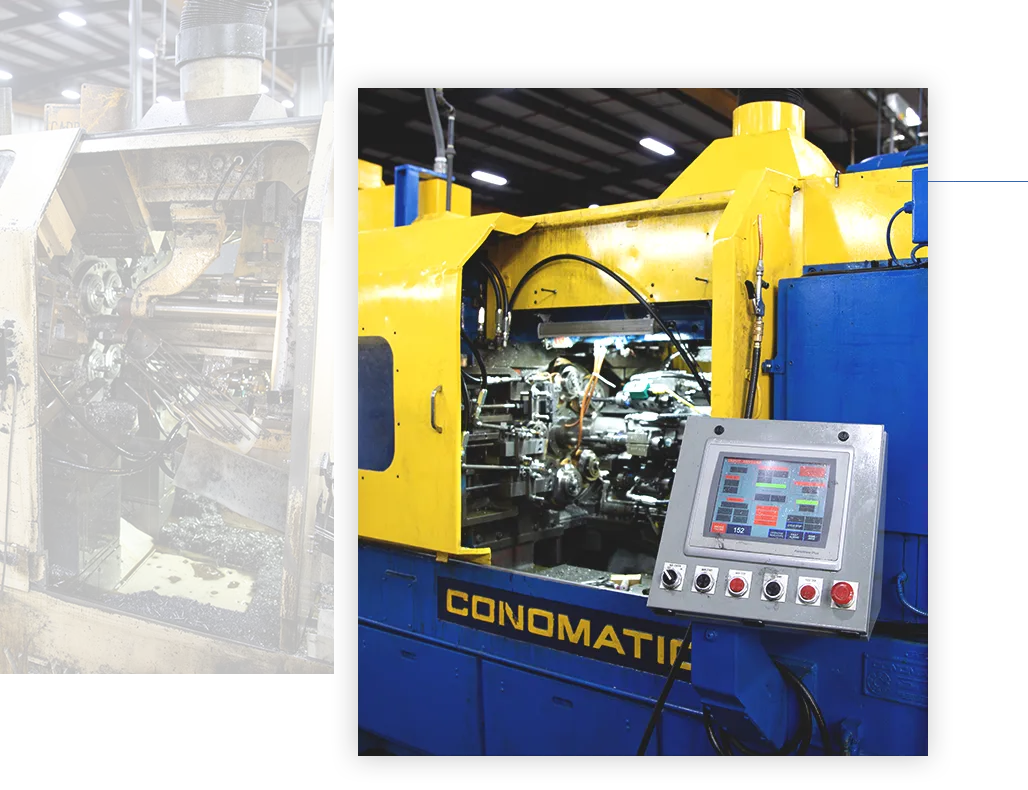

High-Volume Screw Machining

Our Capabilities

- Cycle times as quick as 3.7 seconds

- Heavy material removal

- CNC machining on multi-spindle screw machines

- Average set-up time less than 4 hours

- 1,000+ set-ups per year over 30 primary machines

- Product flexibility over multiple primary machines

- Low set-up times increase machine capacity

- Fault and defect detection switches

- Variable feed drive units and PLC control panels

- Independent spindle drives for deep hole drilling

Contact Vanamatic

Learn more about our screw machining capabilities, request a quote, and more.